Ultrasonic NV Measurement System

Ultrasonic NV measurement system enables automated E-Coat paint feeding

The ultrasonic NV measurment system measures the Non-Volatile (NV) elements of the E-Coat paint. It is configured to feed the E-Coat paint when the NV measurment value reaches the low limit. This allows lowering of the maintenance cost and a stable paint feeding process.

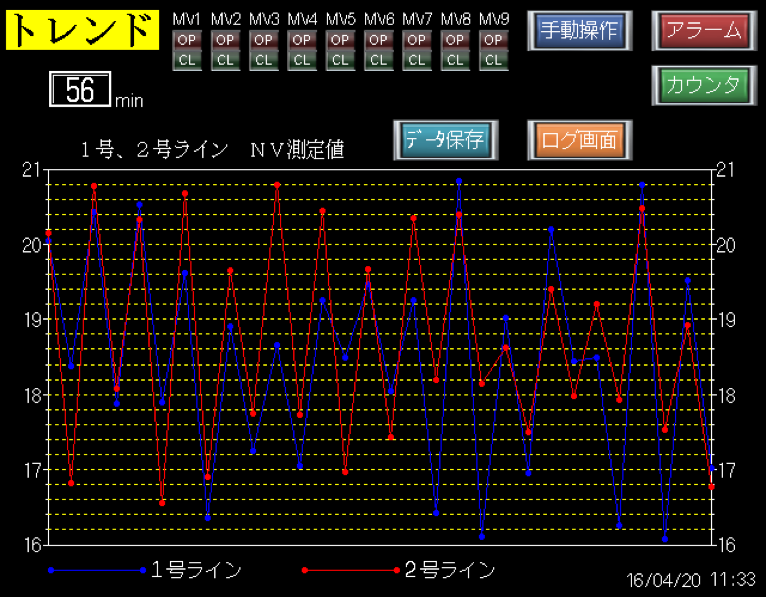

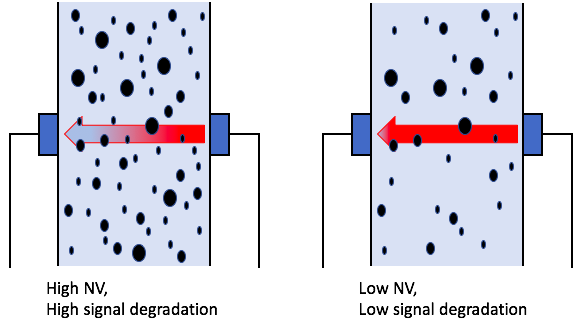

How it works

Inside an E-Coat paint piping, an ultrasonic signal is sent out from one side of the piping, and receives the signal on the opposing side. The signal attenuation rate measures the concentration level of the obstruction material (NV).

The greater the concentration of NV in the paint, the greater the attenuation (weaker signal). This method allows for stable NV% measurment (accuracy around ±1%)。

Ultrasonic NV Measurment System Specification

| Category | Specification |

|---|---|

| NV Measurment Method | Ultrasonic Densitometer |

| Dimentions | Unit W500xD550XH2000 (in mm) |

| E-Coat paint type | Cathodic/Anodic E-Coat Paint NV% measurment accuracy ~±1% |

| Operating Mode | 24 hours/day Continuous Operation, NV value logging, data output in USB memory stick (CSV file) |

| Paint Cerculation Amount | Less than 10L/min |

| When Stopped | Flushing with DI water and stop (short period of stoppage does not requrie flushing) |

| Operating Pressure | 0.1~0.25MPa (No NV value variation due to pressure change) |

| Error Detection | ① Detects moter valve error ② Detects E-Coat Bath/Tank surface level error ③ Sequencer error detection |

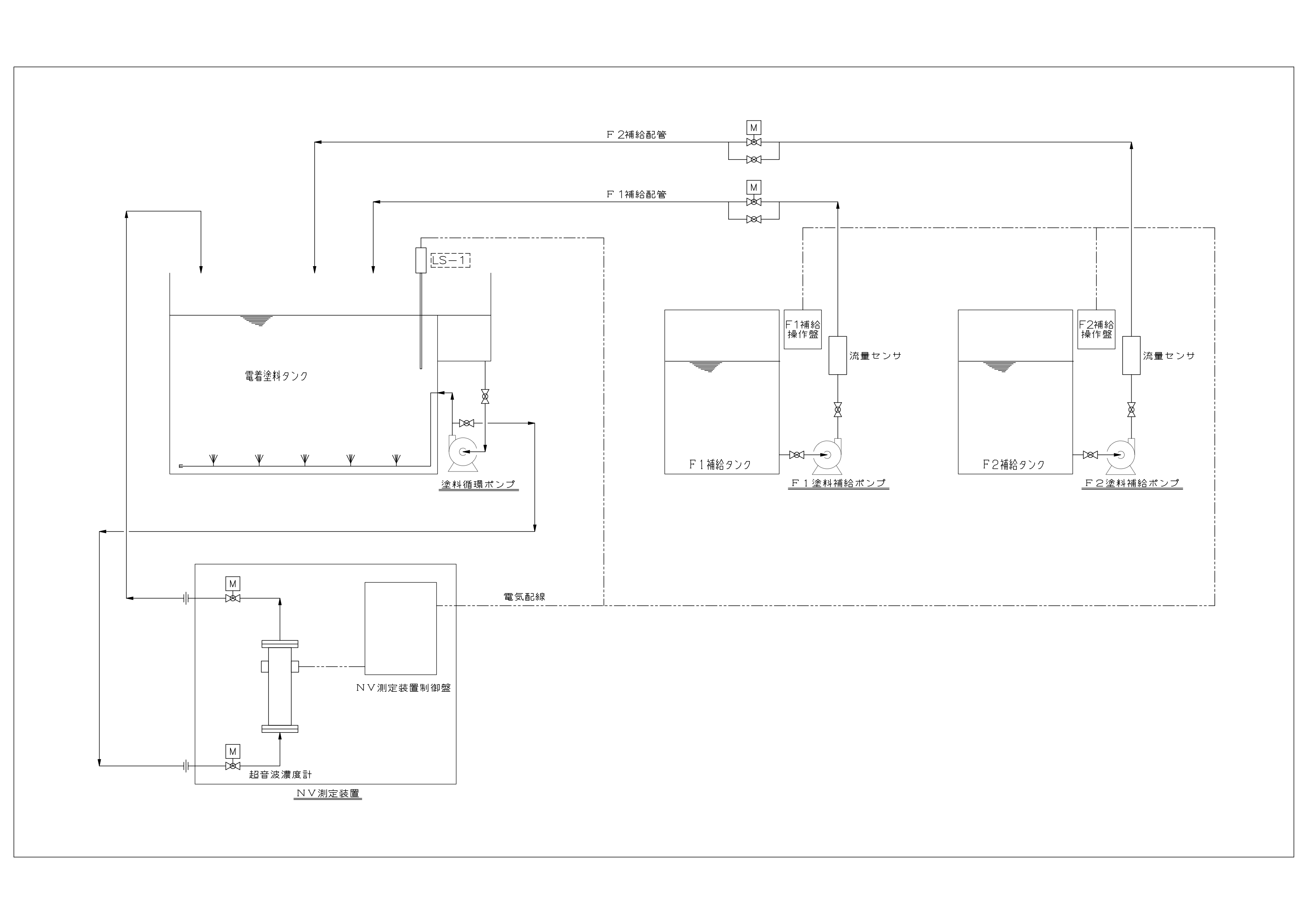

System Flow Diagram (Sample)

CONTACT

![]()

![]()

![]()