RO System HiSep

Easy & Economical Operation

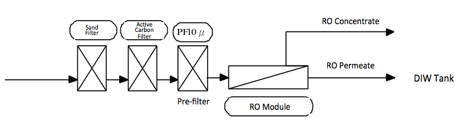

Our Reverse Osmosis (RO) System continuously produces DI water for Industrial purposes without regularly recharging the filter element with acidic/basic chemicals.

The RO module clogging can be flushed in-system in the event of clogging. The RO Module is expected to last around 5 years with normal usage.

PolyTechs RO System Features

- Easy introduction

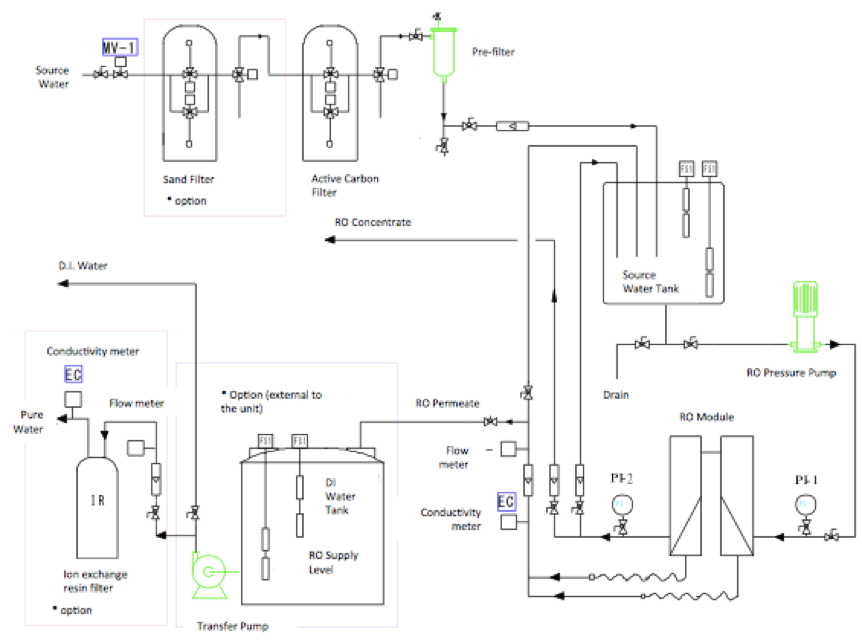

The standard configuration includes automated active carbon filtration and the source water tank. For operation, simply connect the water supply inlet, the RO concentrate and RO permeate outlets.

- Reusing the concentrate

The RO concentrate can be used for other processes since chemicals are not used for pre-processing. *This depends on the source water characteristics.

- In-system module flusing

The system is designed with in-system RO module flushing capability. Even in the event of module clogging, the flushing mechanism will remove the scale to sustain stable permeate production.

- Easy Operation

The simple touch panel interface achieves intuitive and easy system operation. The operation records and system status can be easily accessed and monitored.

- Easy Maintenance

Ease of maintenance is give high priority in the system designing process.

- Use it as Pre-filtering system

The RO system can be used as a pre-filtering system for ion exchange resin purification systems.

- Proper testing before introducing

The source water is tested in the lab prior to and during the system design to ensure expected operation of the DIRO system.

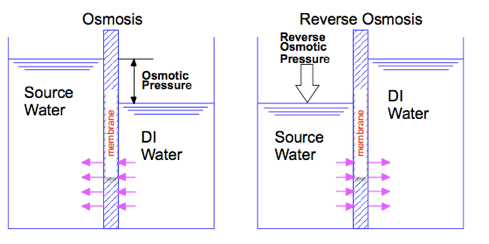

How RO works

In the natural osmotic process, the solvent moves from an area of low solute concentration to an area of high solute concentration via a semipermeable membrane. This happens as the pure solvent is driven to reduce the free energy of the system by equalizing solute concentrations on each side of a membrane, generating osmotic pressure.

Reverse osmosis, reverses this process. By applying high pressure on the high solute concentration side, it reverses the natural flow of the solvent resulting in the solvent moving from the high solute concentration to the low concentration.

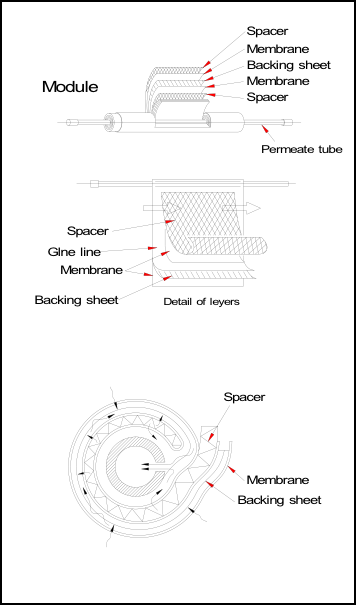

RO Module

● RO membrane has 0.0001µm pours which helps to filter the permeate and concentrate.

● In most cases at least 5 years of sustained permeate production in both volume and quality is expected under normal use. *This depends on the source water quality.

| Category | Specification |

| RO Inlet Pressure | 0.7 ~ 2.5 MPa |

| RO Outlet Pressure | 0.7 ~ 2.5 MPa |

| Module Type | Spiral Type |

| Membrane Area | 7.0m²/module (4 inch) |

| 37m²/module (8 inch) | |

| Operating Temperature | 10 ~ 25 ˚C |

| Permeate Production | 2.5 ~ 5.0 L/min・module (4 inch) |

| 10 ~ 20 L/min・module(8 inch) | |

| Membrane Material | PA, PVDF |

| Chlorine Removal Rate | Above 99% |

| Electrical Conductivity | below 1/20 of the source water |

| Recycle Rate | 50 ~ 75% |

RO System Specification

| Category | PRO-1-4040 DI | PRO-2-4040 DI | PRO-1-8040 DI | PRO-2-8040 DI |

|---|---|---|---|---|

| RO permeate production | 150 ~ 250 L/hr | 300 ~ 500 L/hr | 800 ~ 1200 L/hr | 1500 ~ 2400 L/hr |

| Module Config. | 4" x 1 module | 4" x 2 modules | 8" x 1 module | 8" x 2 modules |

| Power Requirment | 1.5 kW | 1.5 kW | 3.0 kW | 3.0 kW |

| Source Water Quantitiy | *Recycle Rate50% : RO permate x 2 | |||

| Source Water Pressure | 0.2 ~ 0.35 MPa *If inlet pressure does not meet requirement levels a special source water supply unit is necessary |

|||

| Operating Pressure | 0.7 ~ 1.5 MPa | |||

| RO Pressure Pump | 30 L/min x 120 m | 60 L/min x 150 m | ||

| Pre-filter | Cartridge Type 10µm x 500mm x 1unit |

Bag filter Type element 10µm x 1unit |

||

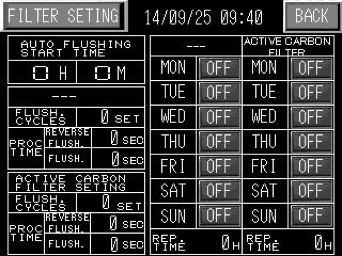

| Active Carbon Filter | 30L Auto Flushing | 60L Auto Flushing | 90L Auto Flushing | 150L Auto Flushing |

| Materials | Frame: SS Pump・Pluming: SUS304・SCS13・PVC | |||

| System Dimensions (mm) |

W650 x L1400 x H1800 | W650 x L1400 x H1800 | W1100 x L1800 x H1800 | W1100 x L1800 x H1800 |

● Cartridge type ion-exchange filteration unit: less than 1µS/cm

| IRM-25 | IRM-50 | IRM-75 | |

| Resin quantity | 25 L | 50 L | 75 L |

| RO permeate needed | 25 ~ 50 m³ | 50 ~ 100 m³ | 75 ~ 150 m³ |

● Auto Sand Filtration unit

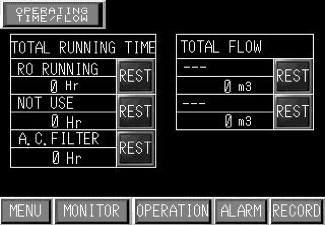

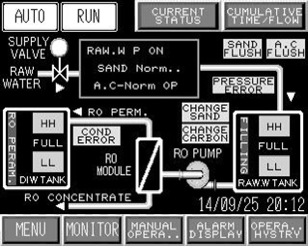

Easy Operation & Maintenance

|

|

● Clearly indicates the operation status ● Provides easy maintenance of the pre-filtering systems via the auto flushing mode ● Logs operation hours and informs when maintenance is recommended ● Controls operation on the panel with a single touch |

|

|

RO Flow Diagram

CONTACT

![]()

![]()

![]()