Consulting Services

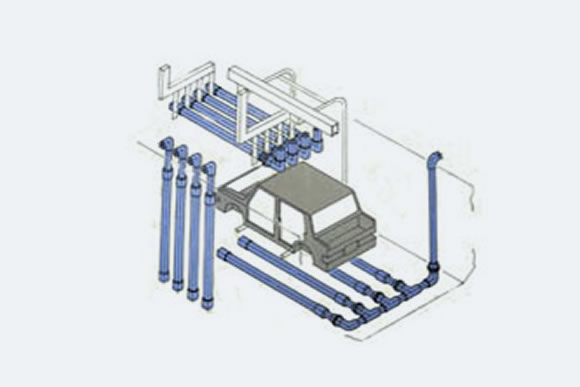

ED Film Thickness Simulation

We have been providing ED film thickness simulation since the '90s and have contributed to the process improvements of many ED lines. We incorporate ED paint data, ED system data, target data and ED operating specification to produce accurate and quantitative film thickness accumulation data.

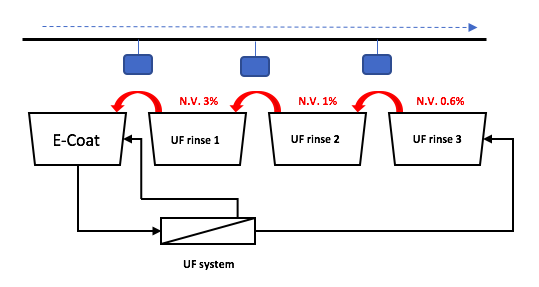

ED Paint Carry Out Simulaiton

UF systems deployed in the ED line is primarily used for excess paint recovery from the target surface. However, assessing and measuring the actual recovery rate can be difficult. We use the actual UF rince water and ED line's operating specifications and simulate the UF rince water N.V.% of each rinse stage. This allows quantifiable data and provides unique insight when predicting/improving the ED line performance.

Consulting for E-Coat Finishing Issues

There are often many+complex factors involved in E-Coat finishing issues. The cause could be due to E-Coat system/equipment problems, insufficient pretreatment, ED paint contamination, not enough rince, not enough "drip" time, etc. We apply our experience and knowledge to assist our customer's E-Coat finishing issues.

CONTACT

![]()

![]()

![]()