Corrosion Resistant Anode PT-DSA

Product Highlights

- Excellent corrosion resistance

- Environmentally Friendly

Conventional stainless steel anode releases heavy metals such as Fe, Ni, Cr, etc during its use. PT-DSA elutes virtually no heavy metals. - Prolong membrane electrode life

The releasing of the heavy metal from the stainless steel anode contributes to membrane clogging. When PT-DSA is used as anode for the membrane electrode, its low ellution rate significantly reduces the membrane clogging, and lenthens membrane electrode product life. - Easy handling

PT-DSA weighs only 1/5 compared to the stainless steel anode. It is also mechanically stronger than some ceramic anodes that easily break/crack.

Design Details

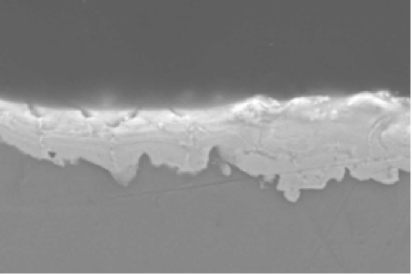

PT-DSA has a titanium substrate which is coated with precious metal oxide. The Precious metal oxides such as iridium oxide and ruthenium oxide have very high corrosion resistance while having very low electrical resistance, creating an ideal protective anode coating suitable for heavy duty application.

The surface of the titanium substrate is first treated, then coated with solution containing perious metal, and finally it is baked to form the coating. This process is repeated many times to achieve excellent anode properties.

| Parameters | SUS316(for comparison) | PT-DSA |

|---|---|---|

| Material | SUS316 | Titanium substrate with iridium oxide |

| Corrosion Rate | 5~200 x 10-6 g/C | 1~10 x 10-8 g/C |

| Anolyte Conductivity | 100µS/cm 以下 | 1000~3000µS/cm |

| Heavy metal in anolyte | Cr, Ni, Fe, etc | trace amout |

| Product Life* | 2~5 years | 7~10 years |

| Mechanical Strength | Very high | high |

| Size & Shape | 48.6Φ Pipe | 27.2Φ Pipe |

Application

Use as bare anode

Effective E-Coat paint acid (neutralizer) balance requires a proper ratio of both membrane electrodes and bare electrodes. If too many PT- AN(acid-removal type) membrane electrodes are used, the acid level becomes too low in the E-Coat bath. Bare anodes provide electrical current without removing acid, thus introduction of bare anodes helps to balance the acid level.

Use as anode inside membrane electrode

PT-LAN (low acid removal type): Prevents sludge build-up on anode and help balance the neutralizer.

PT-AN (acid removal type): Able to operate under higher anolyte conductivity and reduce the anolyte disposal to 1/10th. Very little release of heavy metal simplifies anolyte disposal.

Effective E-Coat paint acid (neutralizer) balance requires a proper ratio of both membrane electrodes and bare electrodes. If too many PT- AN(acid-removal type) membrane electrodes are used, the acid level becomes too low in the E-Coat bath. Bare anodes provide electrical current without removing acid, thus introduction of bare anodes helps to balance the acid level.

Use as anode inside membrane electrode

PT-LAN (low acid removal type): Prevents sludge build-up on anode and help balance the neutralizer.

PT-AN (acid removal type): Able to operate under higher anolyte conductivity and reduce the anolyte disposal to 1/10th. Very little release of heavy metal simplifies anolyte disposal.

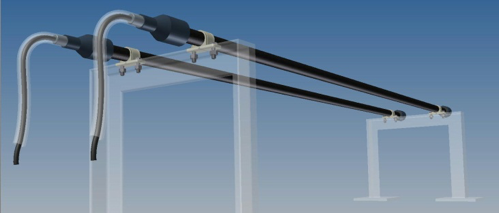

Versatile anode positioning

PT-DSA's light weight combined with its mechanical strength makes it possible to install the anode in a variety of positions. The ability to install the anode in various positions and target certian parts of the work is particularly advantageous for highly demanding coating jobs such as car bodies.

Notes

Important points when installing① Please use PT-DSA in conditions below 50A current per 2m/pipe. When exceeding 50A per 2m/pipe, please increase the number of PT-DSA pipes and distribute the current load.

② PT-DSA manifests its corrosive resistance when used as an anode. When operated as a cathode, it will generate hydrogen on its surface and break the layer of the precious oxide coating. Use caution where PT-DSA is installed.

Handling precautions

Although PT-DSA is light weight and easy to handle, the precious metal coating layer is not strong against mechanical impact and scratching. Please handle with care, and take precautions on points listed below.

① Protect from strong impact

② Protect from impact against hard objects

③ Do not rub or scratch with metal objects

④ Wear gloves when carrying the anode portion

⑤ Protect from oil

⑥ Do not expose to acidic atomsphere when storing

⑦ Do not power-wash

To Clean off the PT-DSA electrode portion, please use solvent or alcohol safe to use with ED paint.

CONTACT

![]()

![]()

![]()